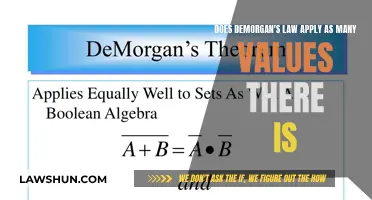

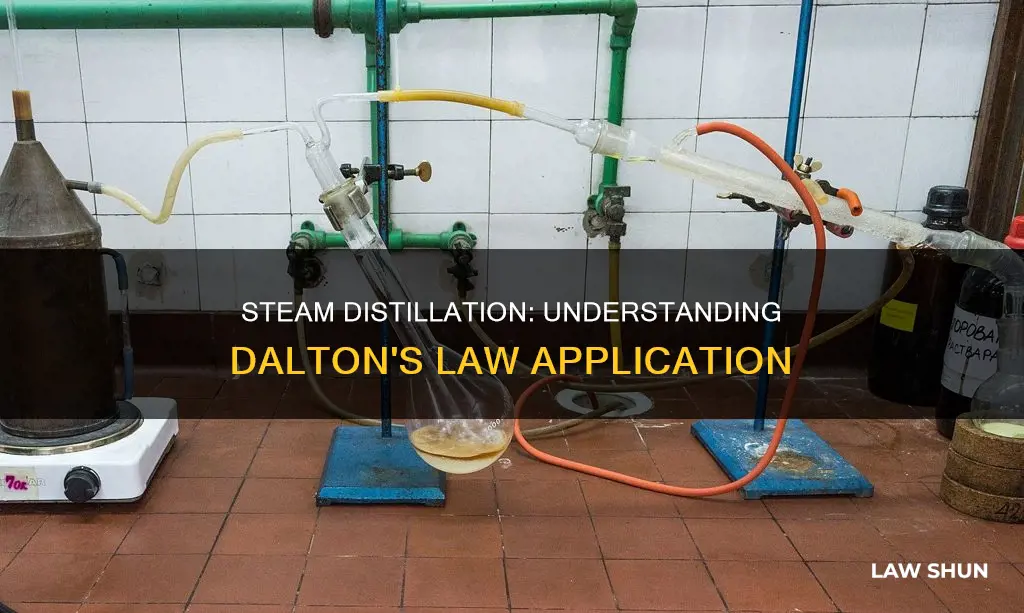

Steam distillation is a widely used technique for the isolation and purification of essential oils. It involves passing steam through an organic liquid that is immiscible with water and collecting the distillate, which contains two separate layers that can then be separated. This process is particularly useful for organic liquids with high boiling points that would otherwise decompose during distillation. The vapours of completely immiscible liquids follow Dalton's law, which states that when non-reacting gases or vapours are mixed, each gas exerts the same pressure as if it were alone, and the sum of these partial pressures equals the total pressure of the system. Dalton's law can be expressed as P=p1 + p2+p3 + ... + Pn, where P is the total pressure and p1, p2, etc. are the partial pressures of the components. This law is applicable to steam distillation as the vapours of the immiscible liquids involved follow it.

| Characteristics | Values |

|---|---|

| Steam distillation | Passing steam through an immiscible organic liquid and collecting the distillate |

| Dalton's Law | When gases or vapours that don't react chemically are mixed, each exerts the same pressure as if alone, and the sum of partial pressures equals total pressure |

| Formula | P=p1 + p2+p3 + . . . +Pn, where P is total pressure and p1, p2, etc. are partial pressures of components |

| Application to Steam Distillation | Steam distillation involves immiscible liquids/gases that follow Dalton's Law |

What You'll Learn

Steam distillation and the isolation of essential oils

Steam distillation is the most popular method for extracting and isolating essential oils from plants for use in natural products. This process involves the vaporization of a mixture, which can be achieved by continuously blowing steam through a mixture or by boiling water and the sample together. Steam distillation is preferred for extracting essential oils because it is environmentally friendly, safe to operate, and easy to scale. It is also better at producing pure compounds and reducing impurities.

The steam distillation process begins by placing the plant material in a large container called a Still, usually made of stainless steel. Steam is then injected through the plant material, releasing the plant's aromatic molecules and turning them into vapour. The vapour travels to the condensation flask, where hot water exits and cold water enters, causing the vapour to cool back into a liquid. The aromatic liquid byproduct collects in a receptacle called a Separator, where the essential oil, which does not mix with water, floats on top and is siphoned off.

Steam distillation is a simple and low-investment method for extracting essential oils, with approximately 93% of essential oils being extracted this way. However, it has some disadvantages, including long extraction times and high energy consumption. Other methods, such as CO2 extraction, may produce higher-quality oils as they are not altered by high heat.

Understanding Crummey Laws: Revocable Trusts and Their Exemptions

You may want to see also

Steam distillation vs. dry distillation

Steam distillation is a type of distillation used for compounds that are sensitive to heat. It is performed by passing hot steam through a mixture, collecting the resulting vapour, and then condensing it. This method can be used to extract oils from natural products such as eucalyptus oil, citrus oils, or other substances derived from organic matter.

Dry distillation, also known as destructive distillation, is a type of distillation that involves heating a substance in a closed container with no oxygen to prevent combustion. This method breaks down or destroys the original substance and produces solid, liquid, and gaseous products. Dry distillation is often used in the You may want to see also Essential oils are hydrophobic, meaning they do not mix with water. This is due to the chemical properties of both substances. Water has high surface tension, which makes it difficult for other liquids to break through and blend. Instead, oils float on top of this barrier. Additionally, the non-polar compounds in oils cannot form bonds with water molecules, so they cannot dissolve in water. However, some oil components, such as esters and aldehydes, can dissolve into water fractions during steam distillation, usually reaching 0.5-1% solubility. This process also alters the oil yield and scent profile. To make essential oils more water-soluble, various methods can be employed, such as adding alcohols like ethanol to reduce oil viscosity and surface tension, using emulsifiers or surfactants to suspend the oil in water solutions, or adding stabilizers to prevent separation. These methods produce "water-soluble" essential oils that can mix with water without floating or separating. However, these oils are no longer 100% natural plant extracts and may have reduced therapeutic potency and purity. One exception to this is flower hydrosols, which are the water remnants from distillation. These floral waters carry mild oil properties despite their solubility in water and are considered natural and safe for the skin. When assessing the quality of essential oils, it is important to consider their purity, composition, and extraction method. Pure essential oils that are cold-pressed or steam-distilled will have higher therapeutic potency and purity. Water-soluble essential oils have gained popularity due to their ease of use in diffusers, humidifiers, and room sprays. However, it is important to remember that these oils are treated with additives, which may impact their health benefits. As such, hydrosols or floral waters are recommended for water-based applications as they are 100% natural and safe. You may want to see also Mathematically, the overall pressure is the sum of the individual partial pressures. For a gaseous mixture: P = p1 + p2 + p3 + ... Where P is the total pressure of the system, and p1, p2, etc., are the partial pressures of the components. Steam distillation is a technique used to isolate and purify essential oils. It involves passing steam through an immiscible organic liquid and collecting the distillate. Many organic liquids with high boiling points decompose when distilled, so steam distillation is used as an alternative method. During steam distillation, the vapours of completely immiscible liquids follow Dalton's law. In this case, the liquid exerts another partial pressure that contributes to the overall measured pressure. The total pressure is the sum of the partial pressures of the liquid and water. The boiling point of a mixture of immiscible liquids is the temperature at which the sum of the vapour pressures is equal to the atmospheric pressure. This temperature is lower than the boiling point of the most volatile constituent on its own. The vapour coming from such a mixture contains all the constituents in proportion to their relative vapour pressures. You may want to see also Dalton's Law of Partial Pressures states that the overall pressure of a mixture of gases is the sum of the individual partial pressures of each gas in the mixture. This law applies to vapour pressure, where the vapour pressure of a liquid is another partial pressure that contributes to the overall measured pressure. Now, let's discuss the boiling point of a system of immiscible liquids. When two immiscible liquids are mixed at a constant pressure of 1 atm, the boiling point of the mixture can be related to the boiling points of the individual liquids in several ways: The vapour pressure of a mixture of two immiscible liquids is independent of their relative amounts. The vapour pressure of the mixture is the sum of their vapour pressures in their pure states. As a result, the boiling point of the mixture is always less than the boiling point of either of the pure liquids and remains constant throughout. You may want to see also Steam distillation is a process used to isolate and purify essential oils. It involves passing steam through an organic liquid that has a high boiling point and is immiscible with water. The distillate contains a layer of water and a layer of the organic liquid, which can then be separated. Dalton's law states that when non-reactive gases or vapours are mixed, each gas exerts the same pressure as if it were alone, and the sum of these partial pressures equals the total pressure of the system. In steam distillation, the vapours of immiscible liquids follow Dalton's law. The vapour pressure of the liquid is a partial pressure that contributes to the overall measured pressure. The formula for Dalton's law is: P=p1 + p2+p3 + ... +Pn, where P is the total pressure and p1, p2, etc. are the partial pressures of the components. Steam distillation allows for the distillation of substances with high boiling points at temperatures below 100 °C. It is also useful for separating compounds that are stable, relatively insoluble in boiling water, and have a vapour pressure of around 1 kPa in boiling water.EEOC Laws: Do They Apply to the President?

The mutual solubility of essential oils and water

Open Carry Laws: Rifles Included or Excluded?

Dalton's Law of partial pressures

Understanding Age of Consent Laws for UK Visitors in the US

The boiling point of a system of immiscible liquids

Vaping vs Smoking: Are Vaping Laws Different?

Frequently asked questions