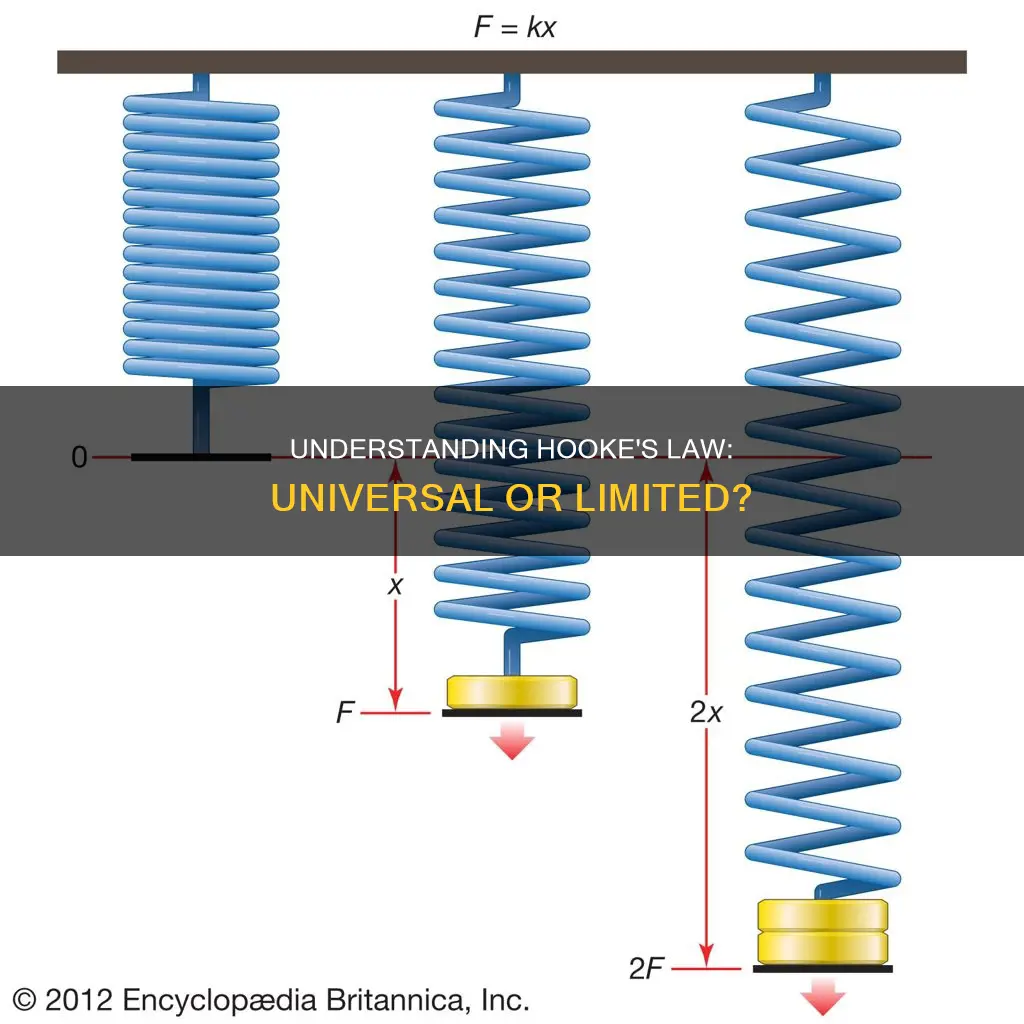

Hooke's Law is a principle of physics that states that the force required to extend or compress a spring is directly proportional to the distance of that extension or compression. Named after 17th-century physicist Robert Hooke, the law is the first classical example of an explanation of elasticity. However, it does not apply to all materials. While many materials obey Hooke's Law, it is only applicable when the load does not exceed the material's elastic limit.

What You'll Learn

Elastic and plastic materials

Elastic and plastic are terms used to describe the properties of materials such as rubber, plastic, and metal. When an external force is applied to the surface of a material, it undergoes a physical change or deformation. If the material returns to its original shape once the force is removed, it is said to be elastic in nature. This property is known as elasticity. On the other hand, if the material does not regain its original shape, it is said to be plastic in nature, and this property is known as plasticity.

Elastic materials can be further characterised by their elastic modulus and elastic limit. The elastic modulus of a material refers to how easily it can be deformed. For example, a steel band has a high elastic modulus, meaning it is difficult to deform, whereas a rubber band has a low elastic modulus and is easily deformed. The elastic limit, meanwhile, refers to the stress value beyond which a material is permanently deformed and no longer behaves elastically.

Plastic materials, meanwhile, have tiny elastic regions, while elastic materials have large elastic regions. All materials exhibit elastic deformation up to a certain limit, beyond which they exhibit plastic deformation. Some materials, like plasticine, have extremely small elastic regions and are therefore considered plastic materials. Others, like rubber, have large elastic regions and are considered elastic materials.

Hooke's Law states that the amount of strain or deformation a material undergoes is directly proportional to the force applied. This means that if twice the amount of force is applied, the material will stretch twice as much. If the loading occurs within the elastic region of the material, when the load is removed, the material will return to its original shape. However, if the material is loaded beyond its elastic limit, the amount of deformation is no longer directly proportional to the force applied, and the material will retain a permanent set, or plastic deformation.

Antitrust Laws: Global Reach and International Application

You may want to see also

Materials that follow Hooke's Law

Hooke's Law, discovered by Robert Hooke in 1660, states that for relatively small deformations of an object, the displacement or size of the deformation is directly proportional to the deforming force or load. In other words, the extension of the spring is proportional to the force applied.

Nearly all materials show Hooke's Law behaviour up to a point. This includes metals such as copper and steel, fibres such as cotton and silk, natural rubbers and polymers.

Wires, for example, obey Hooke's Law because the bonds between the metal atoms act like springs. When the wire is stretched, the bonds lengthen slightly, and when the force is removed, the bonds return to their original length.

Elastic materials, such as rubber, can return to their original shape after being loaded, while plastic materials retain their new shape. For some materials, within their elastic region, the force is directly proportional to the extension, and we say that these materials obey Hooke's Law.

Hooke's Law can be applied to any elastic object of arbitrary complexity, as long as a single number can express the deformation and the stress.

Sunshine Laws: Nonprofit Compliance and Transparency

You may want to see also

Stress-strain diagrams

To construct a stress-strain diagram, a test specimen, such as a cylinder or wire, is subjected to a gradually increasing load, and the resulting deformation is recorded. The stress is calculated by dividing the applied force by the area over which it acts, while the strain is calculated by dividing the change in length by the original length of the specimen. These values are then plotted on a graph, with stress on the y-axis and strain on the x-axis.

The stress-strain diagram of a material that obeys Hooke's Law will have a linear region where the stress and strain are directly proportional to each other. This region falls within the elastic limit of the material, where it will return to its original shape once the load is removed. The slope of the line in this region is known as the Modulus of Elasticity or Young's Modulus.

Materials that obey Hooke's Law include metals such as copper and steel, fibres like cotton and silk, and natural rubbers and polymers. However, even these materials have their limits, and Hooke's Law ceases to apply beyond a certain point. This point of deviation varies for each material and is known as the elastic limit or yield point.

On the other hand, materials that do not obey Hooke's Law, such as rubber, tissue, and aorta, may exhibit a non-linear relationship between stress and strain. In these materials, the elastic region may be very large, but it does not follow the direct proportionality predicted by Hooke's Law. Additionally, such materials may lack a well-defined plastic region, where permanent deformation occurs.

Gas Laws and Celsius: What's the Connection?

You may want to see also

The spring constant

K = Gd^4 ÷ (8D^3 * n)

Where:

- G is the shear modulus or modulus of rigidity of the material

- D is the diameter of the wire used to make the spring

- D is the mean coil diameter of the spring (average diameter of the spring's coils)

- N is the number of active coils in the spring (coils that contribute to the spring's elasticity)

A higher value of k indicates a stiffer spring, which requires more force to produce a given displacement. This is an important consideration when designing mechanical systems where control over motion and force is necessary, such as in valve operations and shock absorbers.

Unclaimed Property Laws: Do Massachusetts Non-Profits Comply?

You may want to see also

Elastic potential energy

Hooke's Law states that the force applied to a material within its elastic region is directly proportional to the extension. Nearly all materials show Hooke's Law behaviour up to a point, including metals such as copper and steel, fibres such as cotton and silk, natural rubbers and polymers.

Elastic energy is the mechanical potential energy stored in the configuration of a material or physical system as it is subjected to elastic deformation by work performed upon it. Elastic energy occurs when objects are temporarily compressed, stretched or otherwise deformed. The energy is potential as it will be converted into other forms of energy, such as kinetic energy and sound energy, when the object is allowed to return to its original shape.

The energy stored in a spring is equal to the work done in stretching it. The work done depends on the average force applied and the extension of the spring. For a material that does not fully obey Hooke's Law, the elastic strain energy can still be calculated by calculating the area under the load-extension graph.

The elastic potential energy equation is used in calculations of positions of mechanical equilibrium. Elastic potential energy in mechanical systems refers to the energy stored in components of mechanical systems that are deformed when forces are applied to the system. A prototypical elastic component is a coiled spring.

Child Labor Laws: Do They Apply to 16-Year-Olds?

You may want to see also

Frequently asked questions

Hooke's law applies to nearly all materials up to a point. This includes metals like copper and steel, fibres like cotton and silk, and natural rubbers and polymers.

Hooke's law is a principle of physics that states that the force needed to extend or compress a spring by some distance is proportional to that distance.

Hooke's law is the first classical example of an explanation of elasticity—the property of an object or material that causes it to return to its original shape after distortion.

The formula for Hooke's law is F= -kX, where F is the force applied to the spring, X is the displacement of the spring, and k is the spring constant.

Hooke's law only works within a limited frame of reference. It does not apply when a material is compressed beyond a certain minimum size or stretched beyond a maximum size without permanent deformation or a change of state.