Gas laws are a group of laws that deal with the behaviour of gases and relate to their pressure, volume, and temperature. These laws are fundamental to understanding various real-life applications, including construction. For instance, when installing a fixed heat-producing gas appliance, such as a gas boiler, it is crucial to ensure compliance with safety regulations and building norms. Gas engineers need to consider the relevant technical guidance documents, gas-related normative documents, and building services compliance guides. Understanding gas laws helps ensure that gas installations are safe and meet the required standards for design, energy efficiency, and structural integrity.

What You'll Learn

Gas appliance installation safety

Gas appliance safety is paramount, and it's important to understand the risks of carbon monoxide and fatal gas leaks. When installing gas appliances, it is crucial to follow these safety guidelines:

Firstly, it is the property owner's responsibility to maintain all piping and equipment inside the home. Gas service providers are responsible for installing and maintaining the natural gas service line up to the gas meter. For any work inside the home, a qualified professional should be engaged to ensure safety.

When adding new gas appliances, it is important to consult with professionals to ensure adequate gas pressure and proper installation. Qualified professionals should always install natural gas appliances, and it is crucial to never attempt this yourself.

Some key safety guidelines to follow include:

- Never install a furnace in a bedroom or where someone sleeps.

- Always consult a qualified professional if you notice any issues with your appliances, such as a yellow flame, the presence of soot, or frequent fan activation.

- Ensure that a qualified professional determines the equipment is properly vented, adjusted, and has adequate fresh air supply for safe and efficient combustion.

- Follow the manufacturer's instructions for safe operation and care of the equipment.

- If you have corrugated stainless steel tubing, ensure it is bonded to reduce the risk of fire or other hazards in the event of a lightning strike.

- Do not reuse flexible appliance connectors; always replace them with new ones when installing new appliances.

When installing common natural gas appliances, such as furnaces, generators, water heaters, or space heaters, it is important to follow specific guidelines:

- Only qualified professionals should install, repair, or service natural gas furnaces and space heaters.

- Always read and follow the manufacturer's instructions, warnings, and warranties for safe operation.

- Ensure that appliances are installed according to local building codes and the manufacturer's specifications.

- Keep combustible items and flammable liquids away from water heaters and other natural gas appliances during operation.

- Choose an insulation blanket specifically designed for natural gas water heaters if insulation is required.

- For older appliances installed in residential garages, ensure burners and ignition devices are at least 18 inches from the floor.

- Do not install unvented natural gas space heaters or logs in bathrooms or bedrooms.

- Remember to turn off natural gas fireplaces and space heaters when leaving the house or going to bed, as they are meant for added warmth and not as a primary heat source.

When replacing or installing a gas stove, there are additional safety considerations:

- Ensure your home has established metered gas service from a utility provider before attempting any installation.

- Locate and shut off the main gas valve to your home before beginning any installation work.

- Always check for gas leaks after installation and before use. Use a gas leak detector or a combustible gas detection wand to ensure safety.

- If possible, have a licensed plumber or a local gas company professional inspect your installation work.

- Install an anti-tip bracket to prevent accidental tipping and potential injury.

- If you are concerned about air quality, consider adding a vent or a ventilation hood above the stove.

- Check with local authorities if venting is required for your gas stove.

Mendelian Inheritance: Multifactorial Traits Explained

You may want to see also

Gas boiler installation compliance

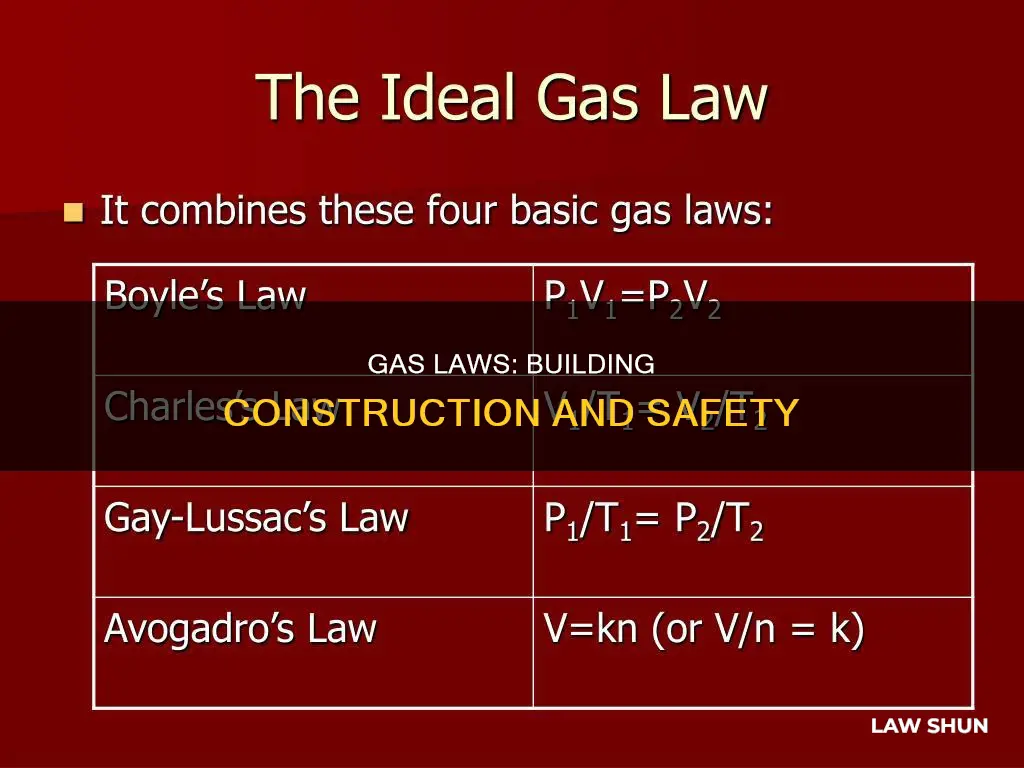

Gas laws, such as Boyle's Law, Charles's Law, and the Ideal Gas Law, are fundamental to understanding various real-life applications. While these laws are crucial in predicting and explaining the behaviour of gases in different conditions, they also have direct implications for construction, particularly in the installation and compliance of gas boilers.

Gas boiler installation is a critical area where gas laws and compliance intersect. Gas engineers and registered businesses must adhere to specific guidelines to ensure the safety and proper functioning of these boilers. Here are the key aspects of gas boiler installation compliance:

Regulatory Compliance

In England and Wales, the installation of any heat-producing gas appliance, including gas boilers, is considered "Building Work" and must comply with the Building Regulations. These regulations are designed to ensure the safety of buildings and protect people's health and well-being. Local authorities must be informed of any such installations, and a Building Regulations Compliance Certificate must be issued. This certificate confirms that the boiler has been installed correctly and safely.

Gas Safe Register

The Gas Safe Register is a crucial organisation in this process. Gas Safe registered engineers or businesses are responsible for notifying the installation of gas boilers. They can do this online or by phone through the Gas Safe Register, and some manufacturers may also offer this service. The Gas Safe Register then informs the relevant local authority.

Timeframe for Notification

There is a specific timeframe for notification. The local authority must be notified within 30 days of the installation. Once the notification is received, the Building Regulations Compliance Certificate should be issued within 10-15 working days.

Engineer's Responsibility

The engineer installing the gas boiler plays a vital role in ensuring compliance. They must register the appliance with the local authorities within the specified timeframe and adhere to the relevant technical guidance documents that support the Building Regulations. This includes ensuring the safety of the installation and complying with associated installation and maintenance standards.

Homeowner's Responsibility

As a homeowner, it is essential to ensure that your engineer notifies the installation to the local authorities and adheres to the Building Regulations. Keeping the Building Regulations Compliance Certificate safe is also the responsibility of the homeowner, as it will be needed when selling or remortgaging the property.

Consequences of Non-Compliance

Non-compliance with the Building Regulations can result in serious consequences. The local authority has the power to prosecute those who carry out work that contravenes the regulations, with potential unlimited fines and prosecution up to two years after the work has been completed. Additionally, the local authority may serve an enforcement notice, requiring the alteration or removal of non-compliant work.

In summary, gas boiler installation compliance is a critical aspect of construction where gas laws and safety regulations intersect. Adhering to the Building Regulations and ensuring proper notification and certification are essential to maintaining safety standards and avoiding legal repercussions.

Leash Laws in Georgia: Do Cats Need Them Too?

You may want to see also

Gas stove installation requirements

Gas stoves require a dedicated gas line connection and metered gas service from a utility provider. The cost of installing a gas line can range from $1000 to $2000, depending on the length of the line. It is important to note that gas is combustible, and a gas leak can be fatal. Therefore, it is recommended to consult a professional for installation if you are uncertain about your ability to complete the project safely.

- Ensure the area is clean and free of debris.

- Locate and shut off the main gas valve to your home.

- Pull out the range and shut off the gas valve to the stove.

- Disconnect and remove the old stove.

- Attach a new flexible gas line to the supply pipe, ensuring it is long enough for easy maneuverability.

- Wrap yellow Teflon tape around the male connector and thread the flexible gas line connector onto the supply pipe connector by hand, being careful not to cross the threads.

- Tighten the connection with an adjustable wrench, ensuring it is snug but not overtightened.

- Connect the flexible gas line to the stove, choosing the correct connector fitting from the kit.

- Thread the connector onto the stove fitting by hand, without using Teflon tape.

- Tighten the connector with an adjustable wrench, again ensuring it is snug but not overtightened.

- Wrap Teflon tape around the square end of the connector and thread the flexible gas line onto it.

- Tighten the connection with the adjustable wrench.

- Turn on the gas and check for leaks using a gas leak detector.

- If no leaks are detected, move the stove into position, being careful not to kink or force the corrugated connector.

- Install an anti-tip bracket to prevent the stove from accidentally tipping over.

It is highly recommended to have your work inspected by a licensed professional, such as a plumber, your local gas company, or a plumbing inspector, even if it is not always required.

Additionally, gas stoves may require venting with a range hood or a microwave with a built-in fan, depending on local regulations. It is important to check with your local plumbing inspector or utility company to ensure compliance with any mandatory venting requirements.

Case Law: Michigan or Florida?

You may want to see also

Gas cylinder safety

Gas cylinders are commonly used on construction sites, especially for welding, cutting, and brazing. However, they can be extremely dangerous and even explosive if not handled, transported, or stored correctly. Here are some detailed safety guidelines to follow when working with gas cylinders in the construction industry:

Transporting and Moving Gas Cylinders:

- Ensure valve protection caps are always securely in place.

- Hoist cylinders using a cradle, sling board, or pallet; never use magnets or choker slings.

- Do not drop, strike, or allow cylinders to strike each other violently. Instead, tilt and roll them on their bottom edges.

- Secure cylinders in a vertical position when transporting them with powered vehicles.

- Do not lift cylinders from one vertical position to another using valve protection caps.

- When frozen, do not use a bar to pry cylinders loose; instead, use warm (not boiling) water to thaw them.

- If cylinders are not secured on a special carrier, remove the regulators and put valve protection caps in place before moving them.

- During use, employ a cylinder truck, chain, or other steadying devices to prevent cylinders from being knocked over.

- Always close the cylinder valve when work is finished, when cylinders are empty, or when they are being moved.

- Keep cylinders secured in an upright position at all times, except briefly when they are being moved, hoisted, or carried.

Storing Gas Cylinders:

- Separate oxygen cylinders, fuel-gas cylinders, and combustible materials (especially oil and grease) by a minimum distance of 20 feet or a non-combustible barrier at least 5 feet high with a fire-resistance rating of at least half an hour.

- Store cylinders inside a building, ensuring they are well-protected, well-ventilated, and in a dry location, at least 20 feet from highly combustible materials.

- Assign specific storage locations away from elevators, stairs, or gangways, where cylinders will not be knocked over or damaged by moving equipment or falling objects, and where they are protected from tampering.

- Do not store cylinders in unventilated enclosures like lockers or cupboards.

- Ensure that cylinders are firmly secured on a special carrier or rack designed for this purpose.

- Keep cylinders far from the actual welding or cutting operation to prevent sparks, hot slag, or flames from reaching them. If this is impractical, provide fire-resistant shields.

- Place cylinders where they cannot become part of an electrical circuit, and never strike electrodes against a cylinder to create an arc.

- Position fuel gas cylinders with the valve end up when in use, and ensure they are not near open flames, hot metal, or other heat sources.

- Do not take cylinders containing oxygen, acetylene, or other fuel gases into confined spaces.

- Do not use cylinders as rollers or supports, whether they are full or empty.

- Only the gas supplier or cylinder owner, or a person authorized by them, should attempt to refill or mix gases in a cylinder.

- Always open the cylinder valve slowly to prevent damage to the regulator.

- Keep oxygen cylinders and fittings away from oil or grease. Ensure that cylinders, cylinder caps and valves, couplings, regulators, hoses, and apparatus are free from oily substances and are not handled with oily hands or gloves.

- Do not direct oxygen at oily surfaces, greasy clothes, or within fuel oil or storage tanks/vessels.

Remember, the above guidelines are a summary, and for a comprehensive understanding of gas cylinder safety, refer to the regulations and standards provided by organizations such as OSHA, CGA, NFPA, and ICC.

Stark Law and Physician Assistants: What's the Verdict?

You may want to see also

Gas cooker notification

Gas laws are a group of laws that deal with the behaviour of gases, specifically relating to the pressure, volume, and temperature of a gas. While these laws are not directly applicable to construction, they are relevant to gas cookers, which are commonly used in the construction industry for various tasks such as soldering, welding, and brazing.

Gas cookers utilise the combustion of a fuel source, typically natural gas or propane, to generate a controlled flame for heating and cooking applications. The understanding of gas laws is crucial for the safe and efficient operation of these appliances.

Boyle's Law

Boyle's Law states that the pressure of a gas is inversely proportional to its volume when the temperature is kept constant. In the context of a gas cooker, this law helps explain the behaviour of the gas as it is supplied to the burner. As the gas flows through the pipe and experiences a change in volume, its pressure adjusts accordingly. This principle is essential for ensuring the gas cooker receives the appropriate amount of fuel for combustion.

Charles's Law

Charles's Law states that the volume of a gas is directly proportional to its temperature. When operating a gas cooker, understanding this law is crucial for controlling the flame's intensity. As the gas is ignited and its temperature increases, its volume expands, resulting in a larger flame. Conversely, reducing the temperature leads to a decrease in volume and a smaller flame.

Avogadro's Law

Avogadro's Law states that the volume of a gas is proportional to the number of moles of the gas. This law is relevant to gas cookers as it helps determine the amount of gas required for a specific task. By knowing the volume of gas used, one can estimate the number of moles present, ensuring the cooker has sufficient fuel to complete the job efficiently.

Gas Safety and Building Regulations

It is important to note that while gas laws are essential for understanding the behaviour of gases in gas cookers, there are also safety regulations and building codes that must be adhered to when installing and operating these appliances. In the UK, for example, the Gas Safety (Installation & Use) Regulations 1998 (GSIUR) outline the safety requirements for gas installations, and non-compliance can result in sanctions or prosecution. Additionally, notifying the relevant authorities, such as Gas Safe Register, is mandatory for certain installations to ensure safety and compliance with building regulations.

Small-Scale Systems and the Second Law of Thermodynamics

You may want to see also

Frequently asked questions

The ideal gas law deals with the pressure, volume, and temperature of a gas at low pressures and high temperatures.

The main gas laws are Boyle's Law, Avogadro's Law, Charles' Law, and Amontons' Law.

Gas laws are fundamental to understanding various aspects of construction, especially when dealing with gas-related installations, such as heating systems, boilers, and cooking appliances.

Gas installations must comply with safety regulations, such as the Gas Safety (Installation & Use) Regulations 1998 (GSIUR), and relevant Building Regulations. Non-compliance can result in prosecution or enforcement notices.

Gas laws are crucial in designing gas appliances, such as boilers and cooking ranges, to ensure safe and efficient operation. For example, understanding Boyle's Law helps ensure that gas appliances can handle changes in pressure and volume without compromising safety.